Why Team Alignment Is a Startup's Greatest Competitive Advantage

Discover key continuous improvement frameworks to boost your startup's success in 2025. Learn effective strategies for growth and innovation today!

In the high-stakes world of startups, speed and adaptability are non-negotiable. Yet, many teams drift from their goals, slowed by miscommunication, unclear priorities, and mounting burnout. The difference between scaling and failing often comes down to one core capability: team alignment. This isn't just a "nice-to-have" cultural element; research shows that aligned teams execute twice as fast and that startup survival correlates more with team coordination quality than individual talent. In startups, team alignment isn't culture—it's survival.

But how do you build and maintain this alignment without suffocating your team in meetings and micromanagement? The answer lies in adopting proven continuous improvement frameworks. These systems provide the structure for teams to learn, adapt, and build momentum together. Forget abstract theories; these are the tactical playbooks used by high-performing organizations to turn iterative progress into a decisive competitive advantage.

This article breaks down the most essential continuous improvement frameworks, exploring the science behind why they work and how they can be supercharged with modern tools like SprintDojo. We'll show you how to move from tracking status reports to celebrating wins, transforming your team’s rhythm from reactive to resilient. By integrating these science-backed frameworks, you can turn daily progress into a powerful operational engine, ensuring your team not only stays on track but thrives under pressure. You will learn how to implement structured reflection, foster collective accountability, and create a culture where course correction is a natural, team-driven process.

1. Lean Six Sigma

Lean Six Sigma is a powerhouse hybrid methodology, merging the waste-elimination focus of Lean with the defect-reduction power of Six Sigma. This dual-pronged approach creates a comprehensive framework for optimizing processes. Lean targets the "Eight Wastes" (defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and extra-processing), while Six Sigma uses a statistical approach to identify and eliminate the root causes of defects and minimize process variability.

The result is a system that not only makes processes faster and more efficient but also ensures the output is of consistently high quality. This makes it one of the most robust continuous improvement frameworks available, adopted by global giants to streamline everything from manufacturing floors to complex financial services. It operates primarily through the DMAIC (Define, Measure, Analyze, Improve, Control) project cycle, a structured, data-driven sequence for problem-solving.

Why It Works: A Dual-Focus on Speed and Quality

Unlike frameworks that focus solely on speed or quality, Lean Six Sigma acknowledges they are two sides of the same coin. A process riddled with errors and rework is inherently slow and wasteful, just as a hyper-efficient process that produces faulty products is useless.

By integrating these two philosophies, teams can achieve remarkable results. For instance, General Electric famously saved over $12 billion in its initial years of implementation. Bank of America leveraged it to cut its loan processing time by a significant margin, demonstrating the framework's applicability beyond manufacturing.

Practical Implementation Tips

To successfully adopt Lean Six Sigma, teams should focus on building a supportive culture and demonstrating value quickly.

- Start with Pilot Projects: Don't attempt a company-wide rollout at once. Identify a few high-impact, well-defined problems and run pilot projects. This builds internal expertise and generates early wins, creating momentum for broader adoption.

- Invest in Training: The methodology relies on specific roles and statistical tools. Proper training and certification (like Yellow, Green, and Black Belts) are crucial for success. This ensures team members can speak the same language and apply the tools correctly.

- Secure Leadership Buy-in: Lean Six Sigma initiatives require resources and can challenge existing workflows. Strong, visible commitment from leadership is essential to overcome resistance and ensure projects are aligned with strategic business goals.

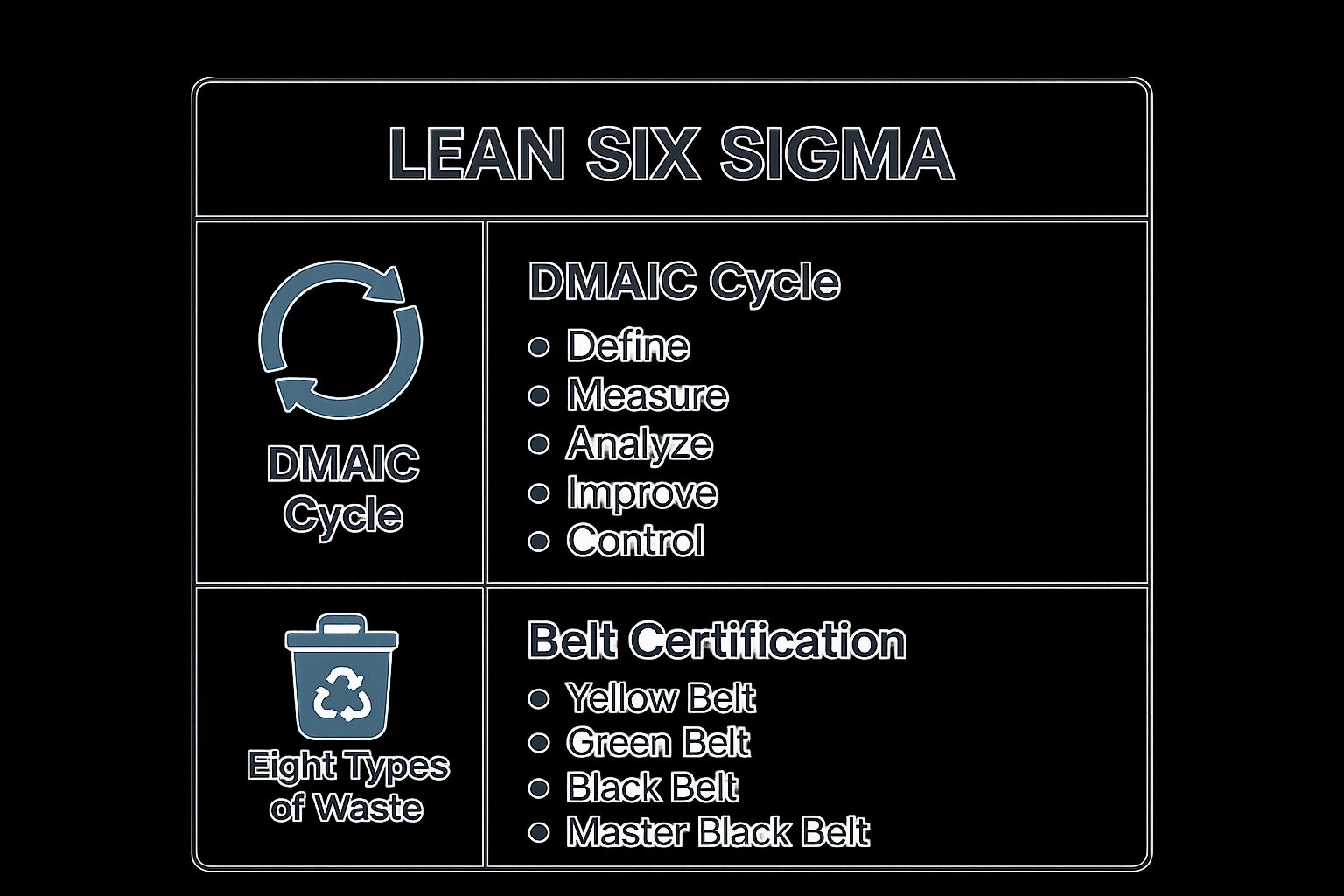

For a quick reference on its core components, the following graphic summarizes the DMAIC cycle, the Eight Wastes, and the certification levels.

This visualization highlights the structured nature of Lean Six Sigma, from its problem-solving cycle to its focus on waste and its system for building expertise. The DMAIC cycle provides the roadmap, the Eight Wastes provide the targets, and the Belt system provides the necessary human infrastructure to drive change.

Key Takeaway: Lean Six Sigma is ideal for organizations dealing with complex processes where both efficiency and quality are critical. It excels in data-rich environments where process variation and waste lead to significant costs, delays, or customer dissatisfaction.

2. Kaizen

Kaizen is a Japanese philosophy centered on the idea that small, ongoing, positive changes can lead to major improvements over time. Rather than seeking revolutionary breakthroughs, Kaizen promotes a culture of continuous, incremental enhancement involving everyone in the organization, from the C-suite to the front-line workers. It is less a project-based tool and more a pervasive mindset focused on eliminating waste (muda) and making processes more efficient and effective every single day.

This approach is powerful because it democratizes improvement. By empowering all employees to identify and solve problems in their own work areas, Kaizen builds a culture of ownership and engagement. This philosophy was famously pioneered and perfected by Toyota, becoming a cornerstone of its legendary production system. It is one of the most foundational continuous improvement frameworks, proving that consistent, small steps can lead to monumental long-term gains.

Why It Works: The Science of Small Wins and Team Momentum

The genius of Kaizen lies in its simplicity and inclusivity. It operates on the principle that the people doing the work are the most qualified to improve it. This avoids the top-down mandate trap and fosters a grassroots movement of problem-solvers. Scientifically, this aligns with the Progress Principle, which shows that recognizing small wins is the single biggest predictor of team motivation. High-performing teams don't just work together—they celebrate progress together.

This collective approach builds incredible organizational resilience. Research by Amy Edmondson shows that when teams share recognition, it increases psychological safety and performance. These shared positive experiences release oxytocin, which strengthens team bonds and builds collective efficacy—a team's shared belief in its ability to succeed. Kaizen turns this into a daily practice, preventing burnout and creating unstoppable momentum.

Practical Implementation Tips

To successfully cultivate a Kaizen culture, focus on empowerment, visibility, and the science of celebration.

- Start with 5S: This method (Sort, Set in Order, Shine, Standardize, Sustain) creates an organized workplace, making process abnormalities and improvement opportunities easier to spot.

- Encourage All Ideas: Create simple systems for employees to submit improvement suggestions. The key is participation; the act of looking for improvements is what builds the culture.

- Conduct Gemba Walks: Leaders should go to "the actual place" where work happens to observe, listen, and show respect. This is for understanding, not for finding fault.

- Replace Status Reports with Win Celebrations: The best teams don't just track tasks; they celebrate what matters. Shifting from surveillance-based reporting to celebration-based recognition transforms team culture. This simple ritual makes progress visible and rewires team motivation and cohesion, preventing the fatigue that plagues so many startups.

Key Takeaway: Kaizen is ideal for organizations aiming to build a deeply embedded, long-term culture of improvement. It excels in environments where employee engagement and the motivational power of small, daily wins are seen as key drivers of competitive advantage.

3. Plan-Do-Check-Act (PDCA) Cycle

The Plan-Do-Check-Act (PDCA) Cycle, also known as the Deming Wheel or Shewhart Cycle, is a simple yet profoundly effective four-stage iterative method for continuous improvement. It provides a straightforward, scientific approach to problem-solving and process optimization. The framework guides teams through a logical loop: planning a change, executing it on a small scale, observing the results, and then acting on what was learned to standardize the improvement or begin the cycle again.

This methodical process makes PDCA one of the most fundamental continuous improvement frameworks. It’s the engine behind the Toyota Production System, where it’s used to refine manufacturing processes relentlessly. Its adaptability also allows it to be used in diverse fields, from enhancing patient safety protocols in hospitals to iterating on software development cycles at companies like Microsoft. The cycle’s strength lies in its simplicity and its emphasis on learning before committing to large-scale changes.

Why It Works: The Science of Team Learning and Course Correction

PDCA works by breaking down improvement into manageable, repeatable steps, encouraging teams to test hypotheses on a small scale. This minimizes risk and fosters a culture of experimentation. The "Check" phase is critical, as it forces a team to pause and analyze objective data. This structured reflection builds what researchers call team metacognition—the team’s ability to reflect on its own processes and adapt.

Without this deliberate learning loop of review and course correction, teams drift from their goals. Research by Hackman and Wageman shows that regular team reflection increases collective accountability and reduces coordination failures. The PDCA cycle is a startup's tactical debrief, providing the structure to ask not just "what happened?" but "what do we do next?" This builds resilience and the ability to adapt under uncertainty.

Practical Implementation Tips

To get the most out of the PDCA cycle, it's essential to maintain discipline and focus on learning at each stage.

- Start with Small, Contained Changes: Don't try to solve a massive problem in one cycle. Identify a specific, manageable issue and formulate a clear hypothesis. This makes the "Do" and "Check" phases far more effective.

- Define Success Metrics Upfront: During the "Plan" stage, clearly define what success looks like. What key performance indicators (KPIs) will you measure? Without clear metrics, the "Check" phase becomes subjective and loses its power.

- Document Everything: Keep a detailed record of each phase: the plan, the actions taken, the data collected, and the analysis. This documentation becomes an invaluable knowledge base for future improvement cycles.

- Standardize Success: If the change proves successful in the "Check" phase, use the "Act" phase to formalize it. Update standard operating procedures, train the relevant team members, and make it the new baseline before moving on to the next problem.

Key Takeaway: PDCA is perfect for teams that need a simple, structured, and low-risk method to start their continuous improvement journey. It is especially effective for building a culture of problem-solving and team metacognition from the ground up.

4. Theory of Constraints (TOC)

The Theory of Constraints (TOC) is a powerful management philosophy that asserts every complex system, from a production line to a software development pipeline, has at least one constraint that limits its performance. This single bottleneck dictates the maximum throughput of the entire system. TOC provides a systematic method for identifying and managing this constraint to elevate overall system output, rather than making isolated improvements that fail to impact the bottom line.

Developed by Eliyahu M. Goldratt in his seminal book "The Goal," this framework shifts focus from optimizing individual parts to optimizing the whole system by managing its weakest link. It operates on the "Five Focusing Steps," a cyclical process for identifying the constraint, exploiting it, subordinating everything else to it, elevating its capacity, and then repeating the process. This makes it one of the most laser-focused continuous improvement frameworks for achieving rapid, systemic gains.

Why It Works: A Focus on System Throughput

TOC's brilliance lies in its simplicity and relentless focus. Unlike other methods that might encourage optimizing every process simultaneously, TOC argues that time spent improving non-constraints is largely wasted. Improving a step that isn't the bottleneck won't make the entire system faster; it will only create more work-in-progress inventory piling up before the constraint.

By concentrating all improvement efforts on the single factor holding the system back, teams can achieve disproportionately large results with targeted effort. For instance, General Motors applied TOC to an engine plant and increased throughput by 50% by identifying and managing its key bottleneck. This philosophy proves that local efficiencies are often irrelevant; only improvements at the constraint directly increase overall system throughput and profitability.

Practical Implementation Tips

Successfully implementing TOC requires a shift in mindset from local optimization to a holistic system view.

- Identify the True Constraint: The first step is a rigorous analysis to find the real system bottleneck, not just a resource that seems busy. This is the part of the process with the longest queue or the least capacity relative to demand.

- Apply the Five Focusing Steps: Use Goldratt's methodology as your roadmap. Once the constraint is identified (Step 1), ensure it's operating at maximum capacity (Step 2: Exploit), and align all other processes to support it (Step 3: Subordinate).

- Use Buffers to Protect the Constraint: A minute of downtime at the constraint is a minute of lost throughput for the entire system. Implement time or inventory buffers just before the constraint to ensure it is never starved for work, protecting it from upstream disruptions.

Key Takeaway: TOC is ideal for systems where flow and speed are paramount and a clear bottleneck can be identified. It is exceptionally effective for organizations looking to increase throughput and revenue without significant capital investment by optimizing existing resources.

5. Total Quality Management (TQM)

Total Quality Management (TQM) is a comprehensive management philosophy centered on achieving long-term success through unwavering customer satisfaction. Unlike frameworks that focus on specific projects, TQM integrates quality improvement into the very fabric of an organization. It involves every member, from the C-suite to the front lines, in consistently improving processes, products, services, and the internal culture.

The core idea is a cultural shift from inspecting for defects to preventing them in the first place. Popularized by quality pioneers like W. Edwards Deming and Joseph Juran, TQM is less a rigid set of tools and more of an all-encompassing commitment to excellence. This makes it one of the most foundational continuous improvement frameworks, aiming to embed quality as a shared responsibility across all business operations.

Why It Works: A Customer-First, People-Powered Philosophy

TQM’s power lies in its holistic and human-centric approach. It operates on the principle that quality is determined by the customer, and achieving it requires the total participation of the entire organization. By empowering employees and fostering a culture of continuous learning, TQM builds a resilient system that proactively identifies and addresses quality issues at their source.

This philosophy has driven significant transformations. Xerox famously used TQM principles to win the Malcolm Baldrige National Quality Award, dramatically improving its market position. Johnson & Johnson's Credo, which prioritizes customers and stakeholders, reflects the deep-seated, customer-first ethos of TQM, guiding decisions across the global enterprise for decades. This demonstrates its power to align a large organization around a central purpose.

Practical Implementation Tips

Successfully implementing TQM requires a deep, long-term commitment rather than a quick, tactical rollout.

- Secure Visible Leadership Commitment: TQM is a top-down initiative that must be championed relentlessly by leadership. Leaders must not only provide resources but also model the desired behaviors and continuously communicate the importance of quality.

- Start with Customer Needs: The entire framework is built around customer satisfaction. Begin by thoroughly assessing customer needs, expectations, and perceptions of quality. Use this data as the North Star for all improvement efforts.

- Invest in Employee Training and Empowerment: Since TQM involves everyone, extensive training in problem-solving, process analysis, and statistical control is essential. Empower employees to identify and fix issues within their own areas of work, fostering a sense of ownership.

- Implement Robust Measurement Systems: You cannot improve what you don't measure. Establish clear metrics for quality and performance across all processes. To learn more, check out our guide on how to measure productivity at work.

Key Takeaway: TQM is best suited for organizations seeking a profound cultural transformation centered on quality and customer satisfaction. It's ideal for businesses where brand reputation is paramount and where long-term customer loyalty is a more critical driver of success than short-term efficiency gains.

6. Business Process Reengineering (BPR)

Business Process Reengineering (BPR) is a radical approach to improvement, focusing on the fundamental rethinking and dramatic redesign of core business processes. Unlike incremental frameworks that tweak existing systems, BPR aims for breakthrough gains in critical performance metrics like cost, quality, service, and speed. It starts with a blank slate, asking, "If we were creating this process from scratch today, what would it look like?"

This methodology challenges deep-seated assumptions and often involves a complete overhaul of jobs, organizational structures, and management systems. The goal is not to improve a process by 10% but to achieve dramatic, order-of-magnitude improvements. It's one of the most transformative continuous improvement frameworks, ideal for organizations facing major market shifts or performance crises that incremental changes cannot solve.

Why It Works: A Focus on Radical Transformation

BPR’s power comes from its "clean sheet" philosophy, which liberates teams from the constraints of legacy workflows. Instead of optimizing outdated steps, it eliminates them entirely and redesigns the process around desired outcomes. To effectively re-engineer processes, a crucial initial step involves utilizing key business process mapping techniques to understand the current state before reimagining the future state.

This radical approach has driven stunning turnarounds. For example, IBM Credit famously re-engineered its financing approval process, reducing the turnaround time from seven days to just four hours. Similarly, Taco Bell redesigned its restaurant operations to shift tasks from the kitchen to central commissaries, allowing staff to focus almost entirely on customer service and doubling restaurant revenue.

Practical Implementation Tips

BPR is a high-risk, high-reward initiative that requires careful planning and execution to succeed.

- Secure Unwavering Executive Sponsorship: BPR challenges the status quo and requires significant resources and political capital. Without strong, visible, and active support from top leadership to drive change and overcome resistance, the initiative is likely to fail.

- Start with High-Impact Processes: Focus initial efforts on processes that directly and significantly impact customers. Redesigning these processes provides the most visible and valuable results, creating momentum and justification for further reengineering projects.

- Invest Heavily in Change Management: The human side of BPR is its most critical component. Invest in comprehensive communication, training, and support to help employees understand the "why" behind the changes and adapt to new roles and responsibilities.

Key Takeaway: BPR is best suited for organizations needing dramatic, not incremental, performance improvements. It is a powerful but disruptive tool for situations where existing processes are fundamentally broken, obsolete, or incapable of meeting new competitive demands.

7. Agile Methodology

Agile is an iterative and collaborative approach to work that prizes flexibility, customer feedback, and rapid response to change. Originally conceived for the fast-paced world of software development, its principles have since been successfully adapted for everything from marketing to manufacturing. Instead of long, rigid planning cycles, Agile focuses on delivering value in short, focused iterations or "sprints."

The core idea is to build, release, and learn in a continuous loop. This makes Agile one of the most dynamic continuous improvement frameworks, as improvement isn't a separate phase but is baked into the very rhythm of the work. For agencies specifically, understanding the Agency-Specific Guide to Software Development Project Management is key, as many of its principles align directly with Agile methodology. By working in small increments, teams can quickly adapt to new information, changing priorities, and customer needs without derailing the entire project.

Why It Works: The Science of Team Autonomy and Course Correction

Agile thrives in environments where requirements are expected to evolve. It acknowledges uncertainty and builds a system to navigate it by empowering self-regulating teams. The best course corrections come from the team, not the manager. Research by J. Richard Hackman shows that self-regulating teams consistently outperform managed teams in complex environments. Agile provides the rituals—like sprints and retrospectives—that help teams self-regulate without top-down control.

This structure builds team autonomy while maintaining sharp focus on goals. It gives teams an early warning system to prevent failures before they cascade. By distributing decision-making, it increases adaptability under pressure. Your team needs someone asking, "Are we still on track?" Agile builds a system where the team becomes that someone.

Practical Implementation Tips

Successfully adopting Agile requires a shift in mindset from following a plan to achieving an outcome.

- Start with Pilot Teams: Avoid a "big bang" organizational rollout. Empower one or two pilot teams to adopt an Agile framework like Scrum or Kanban for a specific project. Their successes and learnings will provide a blueprint for wider adoption.

- Invest in Training and Coaching: Agile isn't just a process; it's a culture. Invest in training and coaching to ensure everyone understands the core principles, roles (like Product Owner and Scrum Master), and ceremonies (like daily stand-ups and retrospectives).

- Prioritize Weekly Reviews: The retrospective is the engine of continuous improvement in Agile. Make these "Weekly Team Truth" sessions a non-negotiable ritual where the team honestly discusses what worked, what didn't, and what to change. Learn more about the power of weekly team reviews.

Key Takeaway: Agile is ideal for teams operating in fast-changing environments where customer feedback and adaptability are critical. It excels at building autonomous, self-regulating teams that can discover the best solution through rapid iteration and continuous learning.

8. Balanced Scorecard

The Balanced Scorecard (BSC) is a strategic performance management framework that moves beyond traditional financial metrics. Developed by Robert Kaplan and David Norton, it translates an organization's vision into a comprehensive set of performance measures across four critical perspectives: Financial, Customer, Internal Business Processes, and Learning & Growth. This approach ensures that short-term financial gains do not overshadow long-term value creation.

By providing a holistic view of organizational health, the BSC acts as one of the most strategic continuous improvement frameworks. It forces leadership to connect the dots between day-to-day operations and high-level strategic objectives. For example, it links employee training (Learning & Growth) to process efficiency (Internal Processes), which in turn impacts customer loyalty (Customer) and ultimately drives revenue (Financial).

Why It Works: A Focus on Strategic Alignment

Unlike frameworks that concentrate solely on operational efficiency, the Balanced Scorecard ensures all improvement efforts are directly tied to strategic goals. It prevents teams from optimizing processes that are not critical to the company's long-term success. This strategic linkage is its core strength, turning a vague mission statement into an actionable, measurable plan.

Mobil (now part of ExxonMobil) famously used the BSC to transform its performance, moving from the worst-performing to the top-ranked company in its industry within two years. Similarly, the City of Charlotte used it to improve public service delivery by aligning departmental efforts with city-wide strategic priorities, demonstrating its effectiveness in both private and public sectors.

Practical Implementation Tips

A successful BSC implementation relies on a clear strategy and a commitment to linking measures in a meaningful way.

- Start with a Clear Strategy: The BSC is only as good as the strategy it represents. Before defining any metrics, ensure your vision and strategic objectives are crystal clear. Use a strategy map to visually communicate the cause-and-effect relationships between objectives.

- Limit Your Measures: Avoid the temptation to measure everything. Focus on a handful of the most critical success factors for each perspective. Too many metrics will dilute focus and create unnecessary reporting burdens, defeating the purpose of strategic alignment.

- Ensure Regular Updates: Strategy is not static. Your Balanced Scorecard should be a living document, reviewed and updated regularly (e.g., quarterly) to reflect shifts in the market, changing priorities, and new learnings. This turns it into a dynamic steering wheel, not a static report.

For teams looking to connect high-level strategic goals with daily execution, exploring effective goal-setting techniques is a crucial first step. You can learn more about setting goals effectively on SprintDojo.

Key Takeaway: The Balanced Scorecard is ideal for organizations seeking to align company-wide continuous improvement efforts with a clear strategic vision. It works best for leadership teams that need to translate long-term strategy into a coherent set of actions and metrics for the entire organization.

Continuous Improvement Frameworks Comparison

| Methodology | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Lean Six Sigma | High - requires extensive training, statistical expertise, and time (6-18 months) | High - needs certified belts, data collection tools, and cross-functional teams | Significant efficiency improvement, waste reduction, and quality enhancement | Manufacturing, Healthcare, Financial Services, Technology | Combines quality and efficiency; structured with measurable ROI |

| Kaizen | Low - simple incremental steps, easy to start | Low - relies on employee involvement and cultural shift | Gradual, sustained improvements with strong team culture and motivation | Startup and tech environments; all industries | Builds employee engagement, momentum, and resilience |

| PDCA Cycle | Low to Moderate - easy to understand but requires discipline | Low to Moderate - depends on project scope | Continuous, iterative improvements with risk mitigation | Any improvement initiative needing structured learning cycles | Simple, adaptable, promotes team metacognition |

| Theory of Constraints (TOC) | Moderate to High - involves mindset shift and complex tools | Moderate - training on Thinking Processes and throughput accounting | Rapid performance gains by removing bottlenecks | Systems with identifiable constraints limiting throughput | Focuses on highest impact areas for rapid results |

| Total Quality Management (TQM) | High - organization-wide cultural change and long-term commitment | High - requires leadership, training, and measurement systems | Long-term customer satisfaction and comprehensive quality culture | Enterprises seeking holistic quality and customer focus | Integrates quality into all business aspects; prevention focus |

| Business Process Reengineering (BPR) | Very High - radical redesign, heavy disruption, and investment | Very High - significant time, resources, and change management | Dramatic performance breakthroughs and process transformation | Organizations needing radical process improvements | Enables breakthrough change and leverages technology |

| Agile Methodology | Moderate - requires cultural shift and training | Moderate - investment in coaching and team organization | Rapid, flexible delivery with high team autonomy | Software development, product teams, adaptable business processes | High responsiveness, team autonomy, and frequent value delivery |

| Balanced Scorecard | High - complex design and linking of strategic metrics | Moderate to High - requires data systems and ongoing management | Balanced view of performance aligning operations and strategy | Organizations needing strategic alignment and performance measurement | Links strategy to operations; promotes proactive management |

From Frameworks to Flow: Building Your Team's Improvement Engine

We've explored a powerful arsenal of continuous improvement frameworks, from the data-driven precision of Lean Six Sigma to the relentless, incremental gains of Kaizen. Each offers a structured path toward operational excellence, providing the strategic blueprints to identify waste, refine processes, and elevate performance. You have seen how TOC helps you pinpoint bottlenecks and how Agile injects speed and adaptability into your projects.

But adopting a framework is only the first step. The true challenge, especially for fast-moving startups, isn't just knowing what to do; it's embedding these principles into your team's daily rhythm. A framework on a slide deck is theory. A framework that lives in your team's actions is a competitive advantage. The goal isn't just to implement a framework, but to achieve a state of continuous improvement that prevents team burnout and builds resilience.

From Team Burnout to Team Flow: How to Build Resilience

High-performing teams don't just grind harder; they celebrate smarter. The most successful teams build a culture where improvement is a shared journey. This is where the science of team dynamics provides a crucial layer on top of classic frameworks. Research like the Progress Principle by Amabile and Kramer highlights that recognizing small wins is the single most powerful motivator for a team. Teams with positive rituals show higher resilience under stress, while regular reflection reduces emotional exhaustion.

This is why traditional, top-down implementation of continuous improvement frameworks often fails. It can feel like another layer of management. The key is to find a system that makes improvement feel less like surveillance and more like a shared celebration. The daily celebration + weekly review cadence protects startup teams from burnout by building recognition, reflection, and course correction into their rhythm.

Key Insight: Your team doesn't need more management; it needs better momentum. The shift from tracking activity to celebrating achievement is the psychological linchpin that turns a rigid framework into a dynamic, team-owned engine for growth and resilience.

Actionable Next Steps: Building Your Improvement Engine

Choosing the right framework is your starting point. Now, it's time to build the engine that runs it. Here’s how you can move from abstract concepts to tangible results:

- Select Your Foundation: Review the frameworks. Are you fighting systemic waste (Lean Six Sigma)? Do you need a simple, repeatable improvement loop (PDCA)? Or do you want to foster a culture of small, daily wins (Kaizen)? Pick one that addresses your startup's most pressing challenge right now.

- Translate Principles into Rituals: Don't just talk about "continuous improvement." Build it into your team's schedule. This is where a system like SprintDojo becomes invaluable. It translates the high-level goals of Agile or Kaizen into lightweight, daily and weekly rituals. Replace tedious status reports with daily win celebrations. This simple shift addresses The Progress Principle directly, boosting psychological safety and motivation.

- Establish a Feedback Loop: All continuous improvement frameworks depend on feedback. Your team needs to know if its efforts are working. Implement "Weekly Team Truth" reviews focused on honest reflection and course correction. This builds team metacognition—the ability to reflect on and improve its own processes. For tech-driven teams, optimizing your feedback mechanisms with strong CI/CD Pipeline Best Practices is crucial for achieving continuous flow.

- Empower, Don't Micromanage: The ultimate goal is a self-regulating team. Provide the tools and frameworks, but give your team the ownership to execute. When a team sees its own suggestions leading to tangible improvements, its commitment to the process deepens exponentially.

By combining a formal framework with a human-centric system for daily execution, you create a powerful synergy. The framework provides the what, and the system provides the how. You're not just managing a process; you're nurturing a culture of proactive, relentless improvement that protects against burnout and keeps everyone aligned and moving forward. This is how you build an unstoppable team.

Sprint Smarter. Forecast Every Week.

Log wins. Build momentum. Let AI show you if you're on track to hit your sprint goal—before it's too late.

Join the waitlist and be the first to unlock predictive clarity for your team.